TF Vetritalia Processings

Bending, Tempering, Double glazing, Screen printing, Lamination, Grinding and Drilling, Bonding

PROCESSING

Tempering

Tempered glass is the result of a specific creation process that makes glass panes incredibly versatile and robust. The thermal hardening process takes a few seconds: in this time the glass plate after being heated is cooled with air at high pressure, obtaining what in technical jargon is called “tempered glass”.

This process is used to create: shower box, refrigerated counters, shop windows, offices, hotels, restaurants and furniture for boats.

PROCESSING

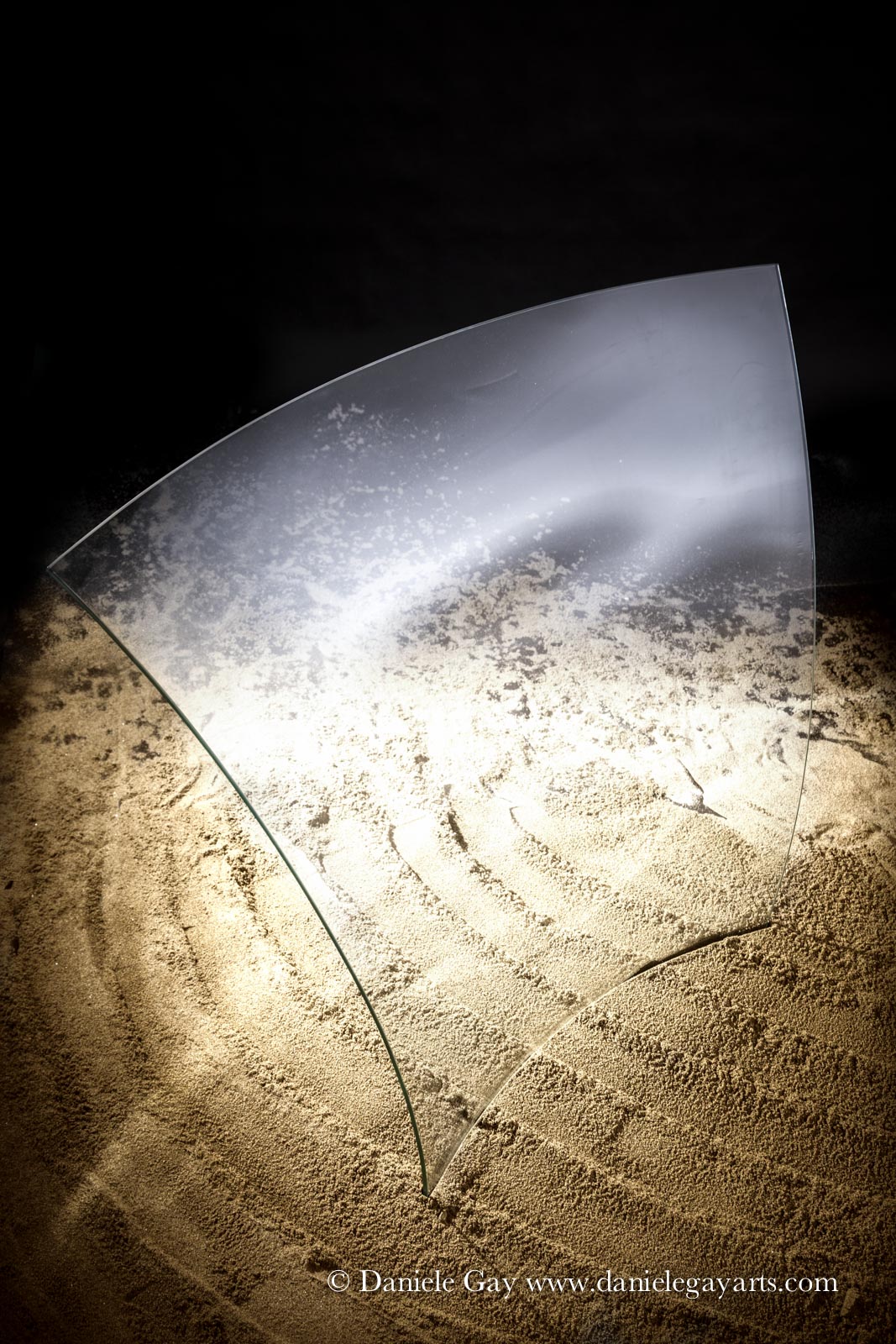

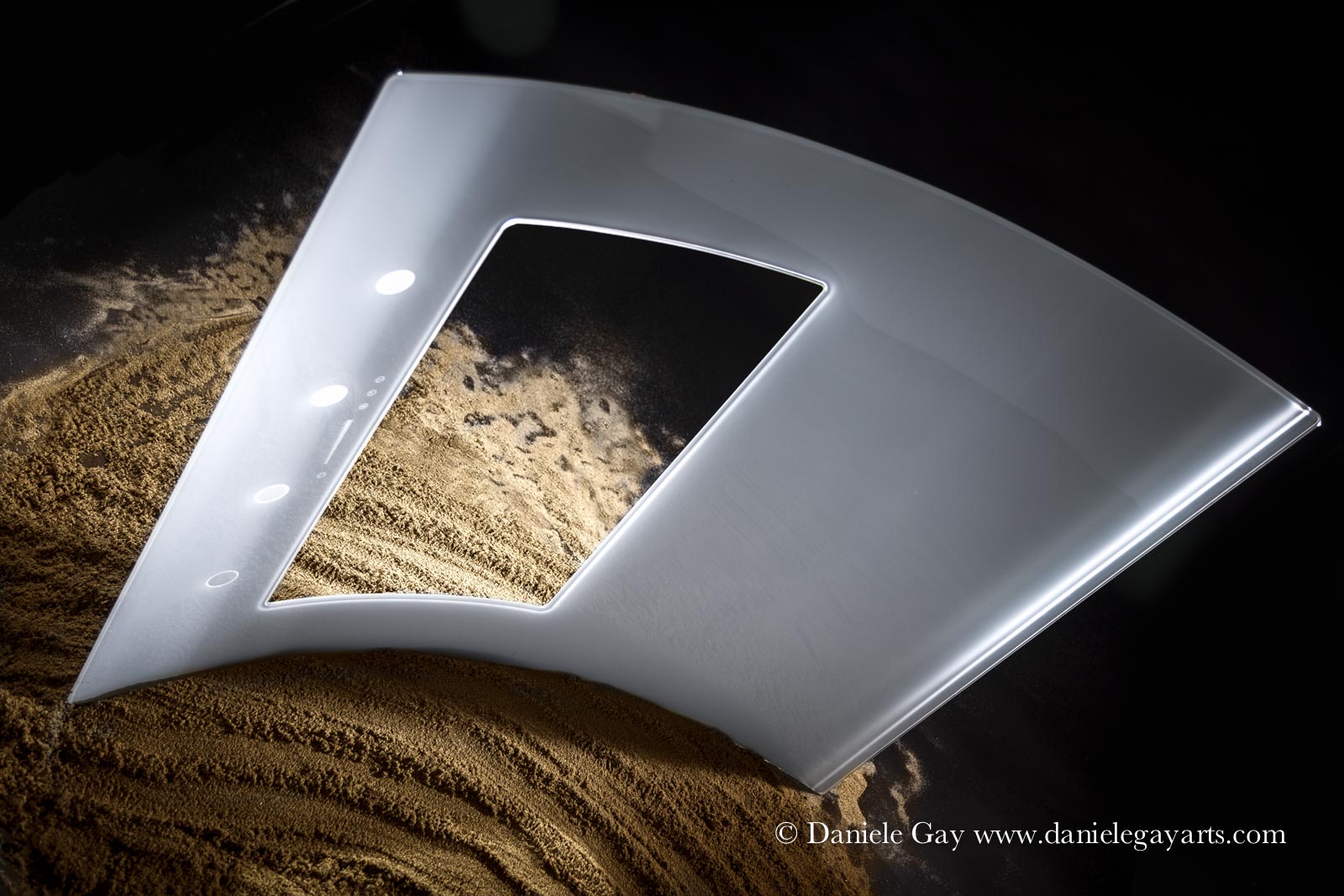

Bending and thermal tempering

In curved thermal tempering, the process involves a bending phase through gravity or a press and ends with an almost instantaneous cooling phase in order to make the glass more resistant and elastic. In fact, the advantages of the glass treated in this way give great resistance to:

- breaking compared to a non-tempered glass sheet. Furthermore, in case of breakage the fragments are small and blunt so as not to injure anyone who comes into contact with them;

- high temperatures;

- pressure;

- mechanical sollecitations.

The features and benefits of curved tempered glass make this product incredibly versatile. TfVetritalia performs machining operations for the shower enclosures and refrigerated counters flat and curved, appliances, shipbuilding, interior and exterior architecture.

PROCESSING

Glass double glazing

The flat and curved double glazing is a glass panel consisting of two or more sheets joined together on the perimeter by means of a spacer frame made of metal, all closed on the perimeter by special sealants.

The version made with low-emissivity coated glass is very popular, which has the power to strongly reduce heat loss.

PROCESSING

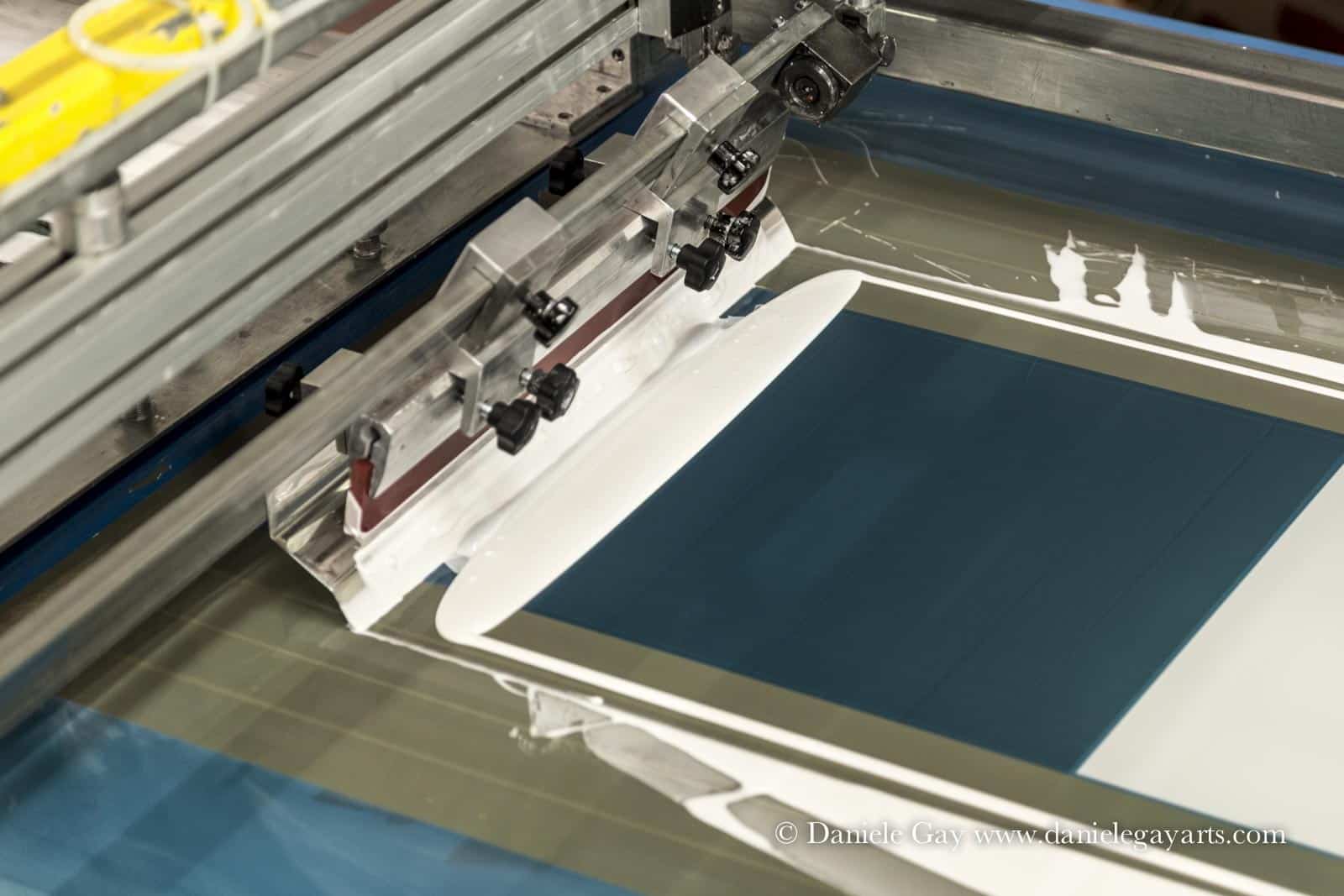

Silk-screen printing

Silk-screen printing is a traditional method for decorating glass in which glazes are applied to part of a surface. This creates interesting possibilities for customization.

PROCESSING

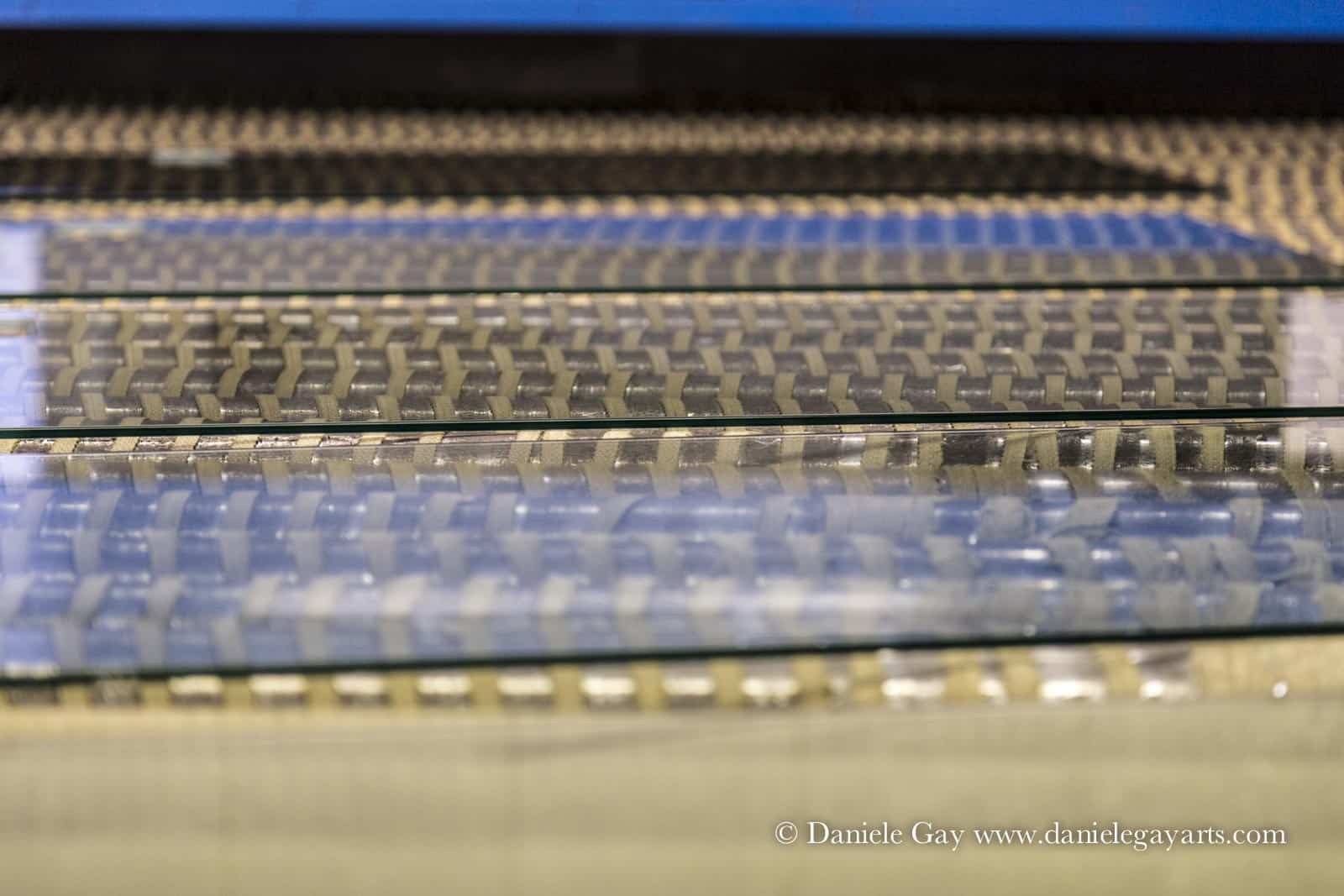

Lamination

Laminated glass is safety glass and is also known as shatter-proof glass. It is made by joining two or more panels of glass together using one or more layers of adhesive plastic film (EVA or PVB) which is applied with heat.

Laminated glass has applications in the refrigeration sector and, above all, in the field of architecture. It functions as structural glass which allows features such as:

- cladding panels for balustrades and spiral staircases,

- roofs for bus stop shelters,

- entrance doors in condominium buildings,

- facades

- and much more

Laminated glass is used for public and private interior design elements such as:

- partition walls,

- full-height glass structures,

- walls units,

- public toilet partitions,

- etc.

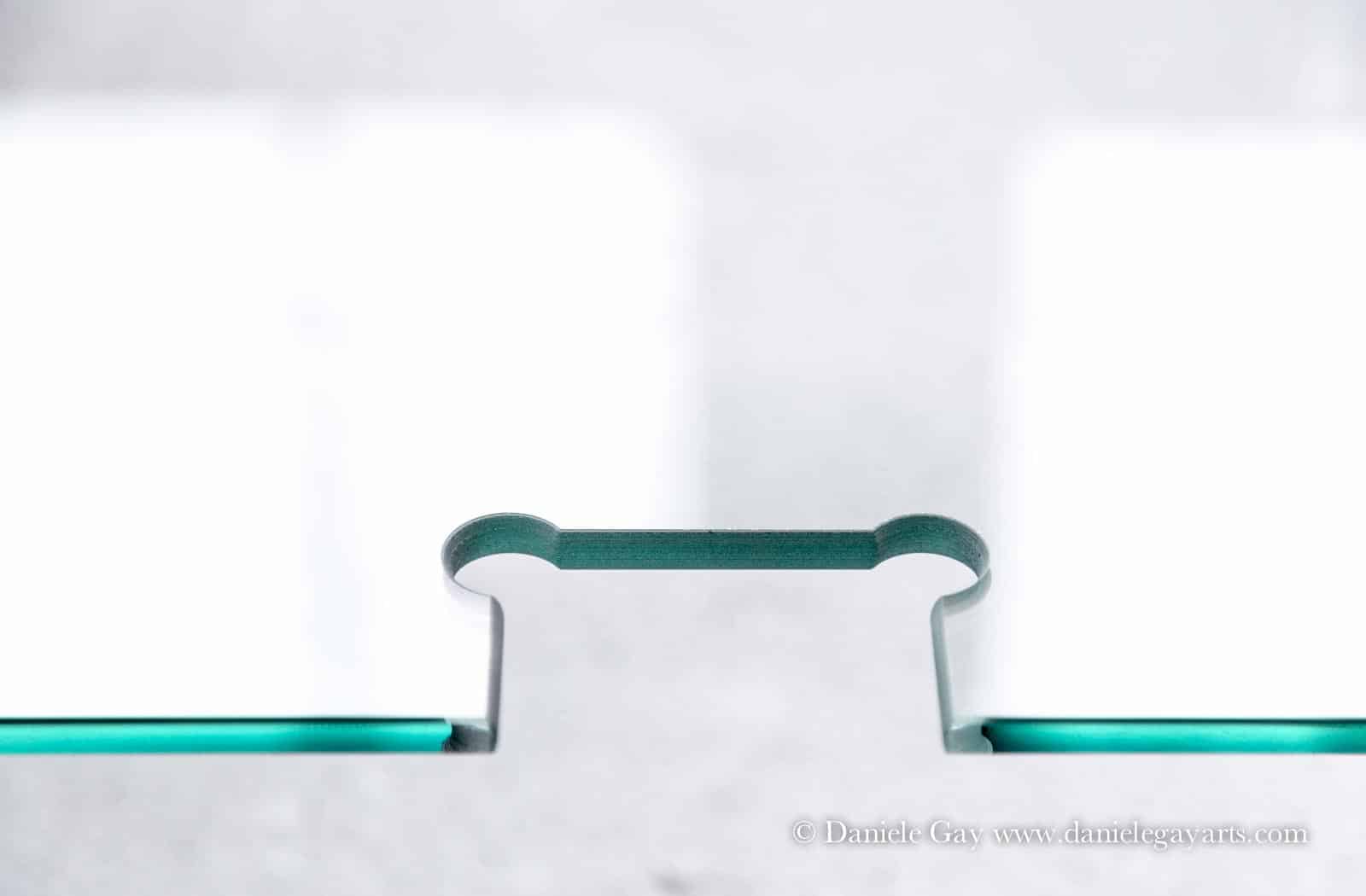

PROCESSING

Grinding and Drilling

La molatura può essere eseguita:

• a round polished edge;

• a flat polished edge;

• a 45° degree edge: the inclination can vary depending on the design needs;

• profiled edge: the edges of the glass are ground to 10-40 mm in height and an angle of 5/7 mm with respect to the glass itself;

In drilling, the numerically controlled diamond bits perform regular cyclic holes, countersunk holes, slots, notches and also very particular recesses, taking into account the design requirements. The holes are said to be countersunk if they have different diameters.

PROCESSING

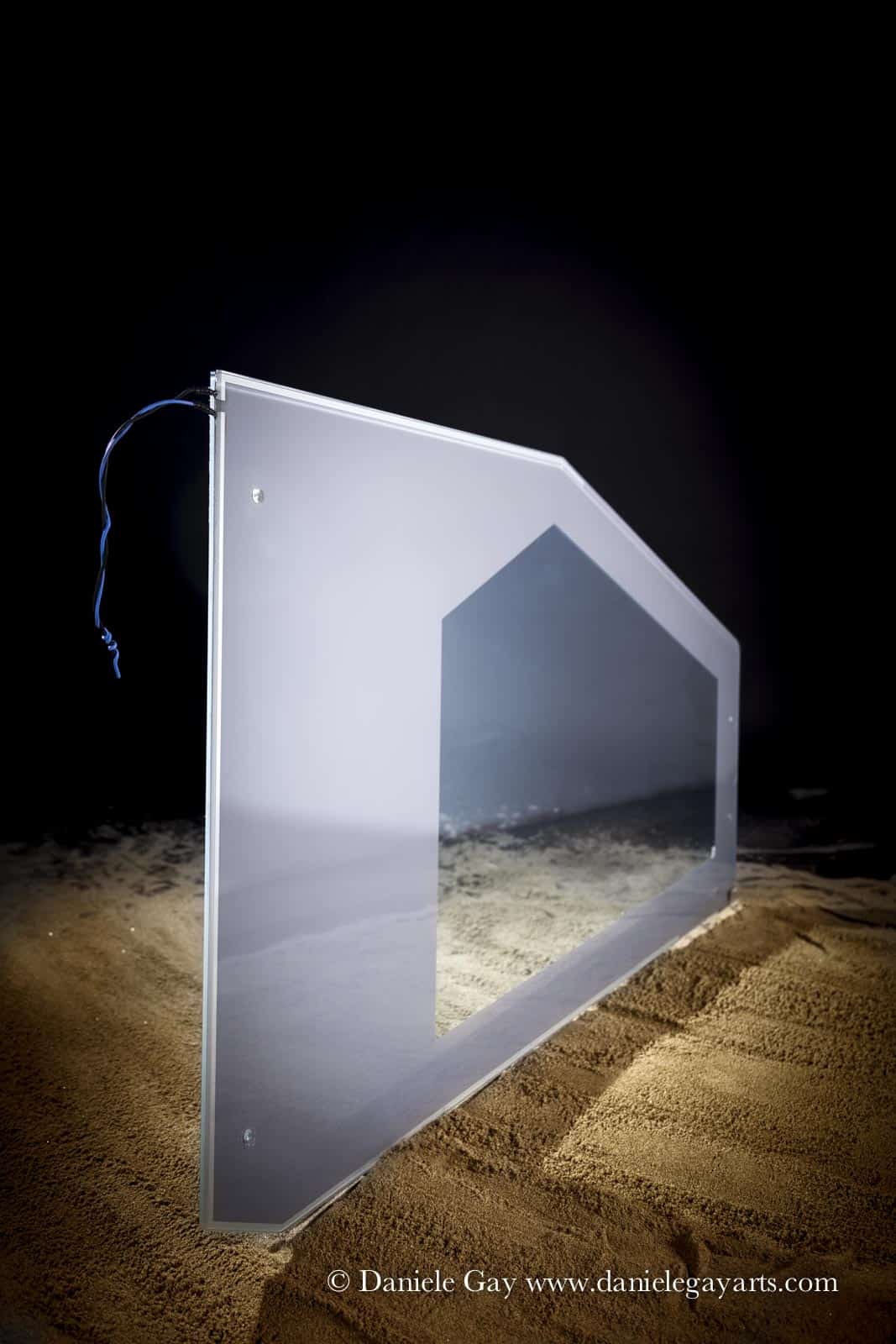

Bonding

Our company has always produced glasses bonded together using UV technology. This technique allows obtaining a clean and clear product with high mechanical resistance properties.We can also bond glass to metal, aluminium and general plastic profiles and parts.

Our display cases are made in a purely customized form, using glass of the most varied finishes and shapes: clear, colored, low iron content, tempered but also curved tempered top.