Le lavorazioni di TF Vetritalia

Curvatura, Tempra Termica, Vetrocamera, Serigrafia, Laminazione, Molatura e Foratura, Incollaggio

LAVORAZIONE

Tempra Termica

Il vetro temperato è il frutto di un processo di creazione specifico che rende le lastre di vetro incredibilmente versatili e robuste.

Questo tipo di lavorazione serve trova applicazione nel mercato dei produttori di box doccia e banchi frigo, dell’arredo di negozi, uffici, hotel, ristoranti e imbarcazioni.

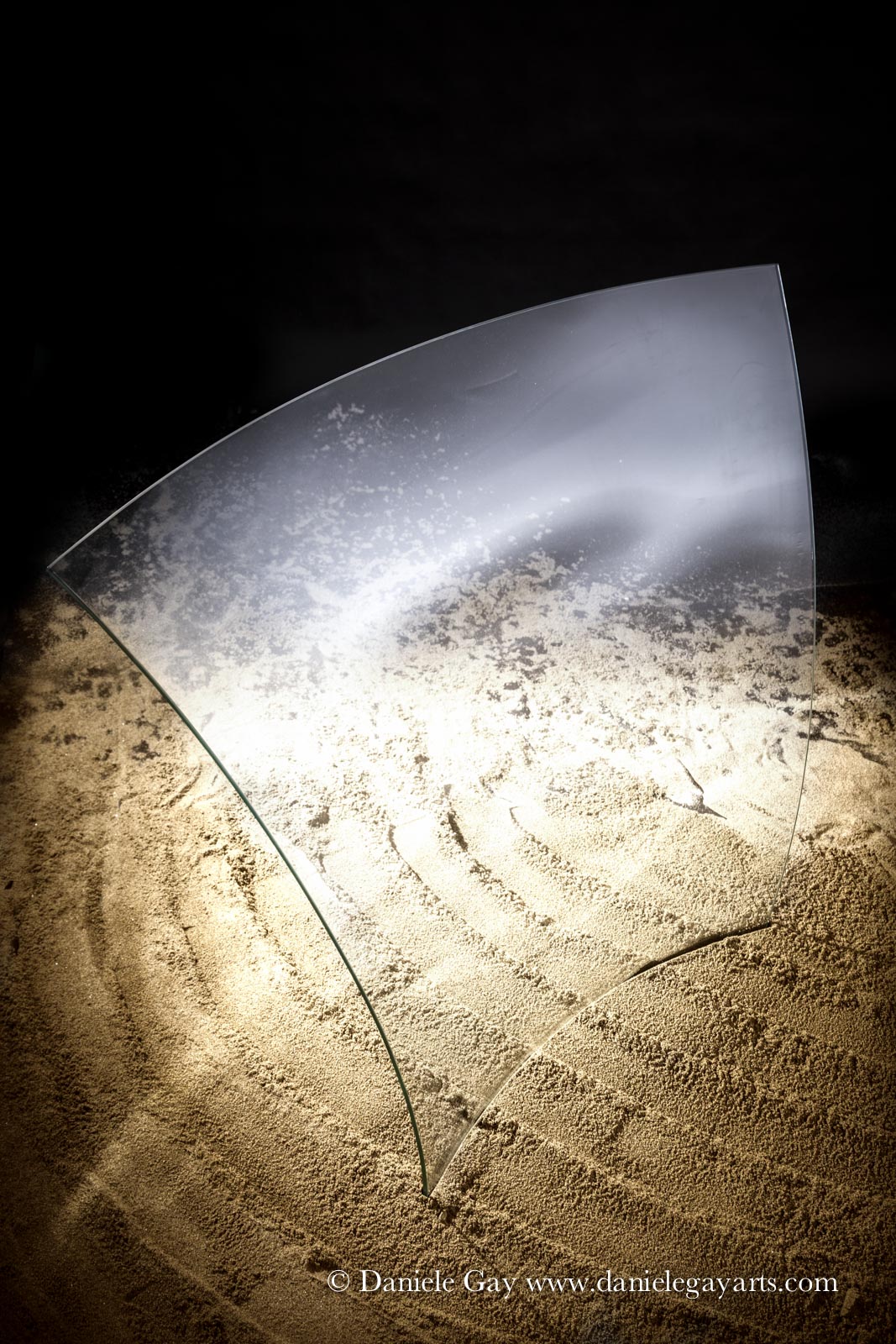

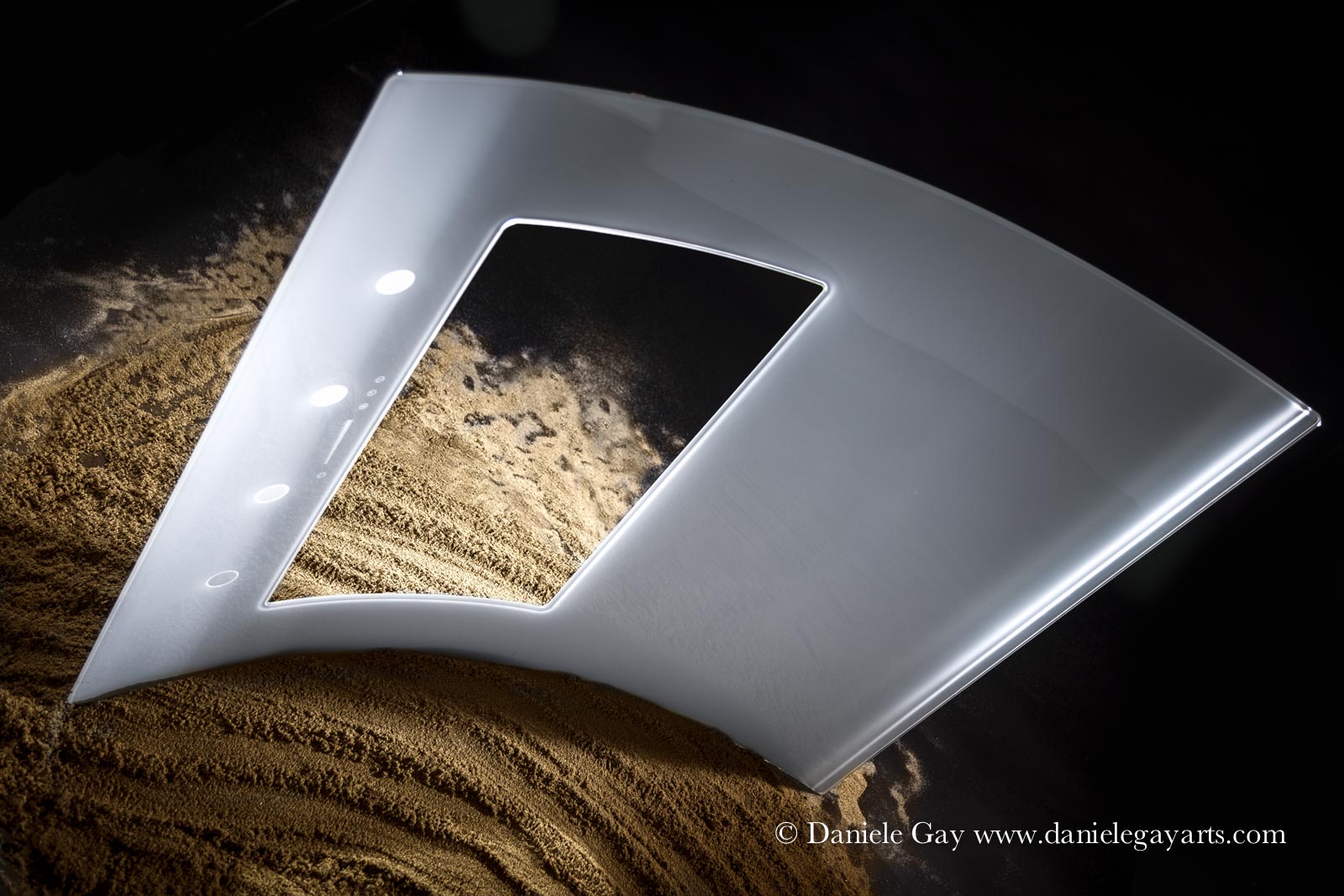

LAVORAZIONE

Curvatura e tempra termica

Le caratteristiche meccaniche e di design del vetro curvo temperato rendono questo prodotto incredibilmente versatile. Tf Vetritalia esegue queste lavorazioni per i produttori di box doccia, banchi refrigerati, elettrodomestici, imbarcazioni e per l’arredo d’interni ed esterni.

Tutti i nostri prodotti sono Certificati UNI EN 12150-1:2019, la normativa di riferimento europea sul vetro per l’edilizia che definisce le caratteristiche relative alle tolleranze, alla planarità, alla lavorazione dei bordi, alla frammentazione e agli aspetti fisici e meccanici di vetri piani monolitici di sicurezza di silicato sodo-calcico temprato termicamente.

LAVORAZIONE

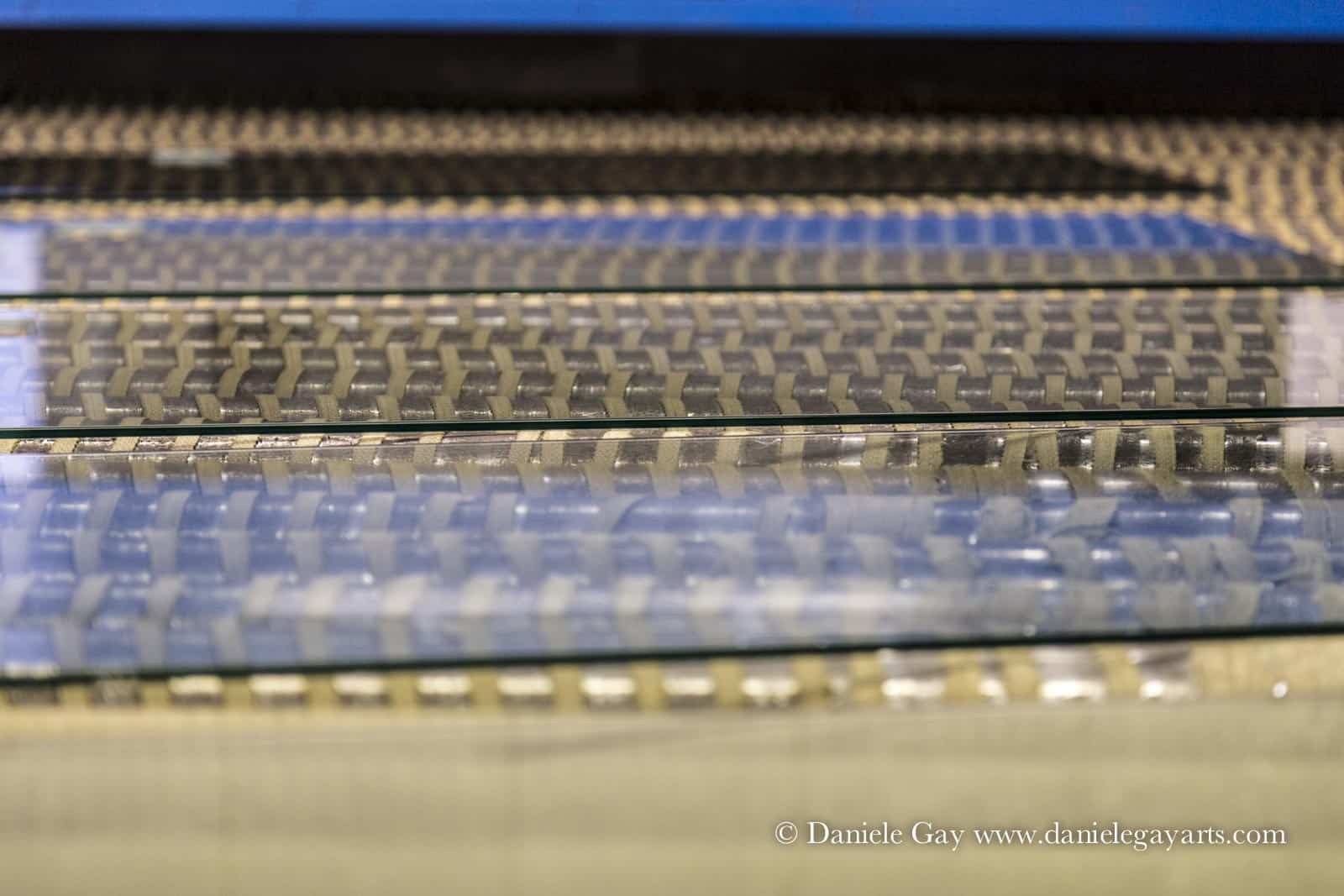

Vetrocamera

Il vetrocamera piano e curvo è un pannello vetrato costituito da due o più lastre unite tra di loro sul perimetro da un telaio distanziatore.

Molto richiesta è la versione realizzata con vetri a basso-emissivi.

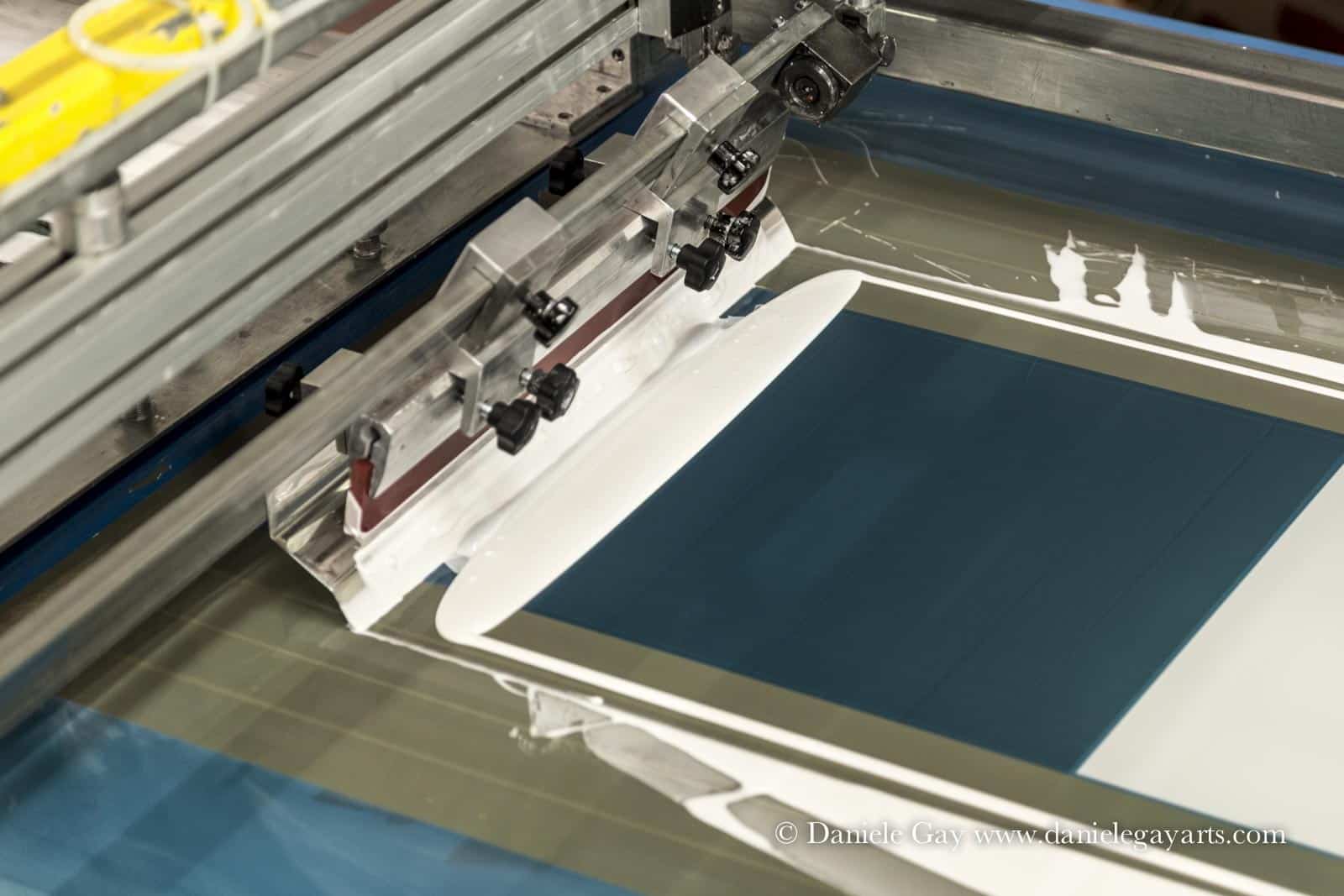

LAVORAZIONE

Serigrafia

La serigrafia serve a decorare il vetro applicando smalti sulla superficie con interessanti possibilità di personalizzazione.

LAVORAZIONE

Laminazione

Il vetro stratificato è un ‘Vetro di sicurezza’ che trova applicazione nella refrigerazione, nel settore dell’architettura e come vetro strutturale nell’arredo d’interni.

Alcune delle sue applicazioni sono:

- pannelli di rivestimento di balaustre e scale a chiocciola;

- tettoie per fermate di autobus;

- porte d’ingresso;

- facciate di edifici;

- pareti divisorie;

- vetrate a tutt’altezza;

- pareti attrezzate;

- divisori per bagni pubblici.

LAVORAZIONE

Molatura e Foratura

Sono lavorazioni il cui scopo è prettamente funzionale, come eliminare il tagliente del bordo e praticare fori od incisioni, ma può anche servire per conferire al bordo del vetro un filo esteticamente in linea con il design del prodotto finito.

Realizziamo molatura, lucidatura, foratura e fresatura delle lastre a seconda delle esigenze del produttore industriale.

LAVORAZIONE

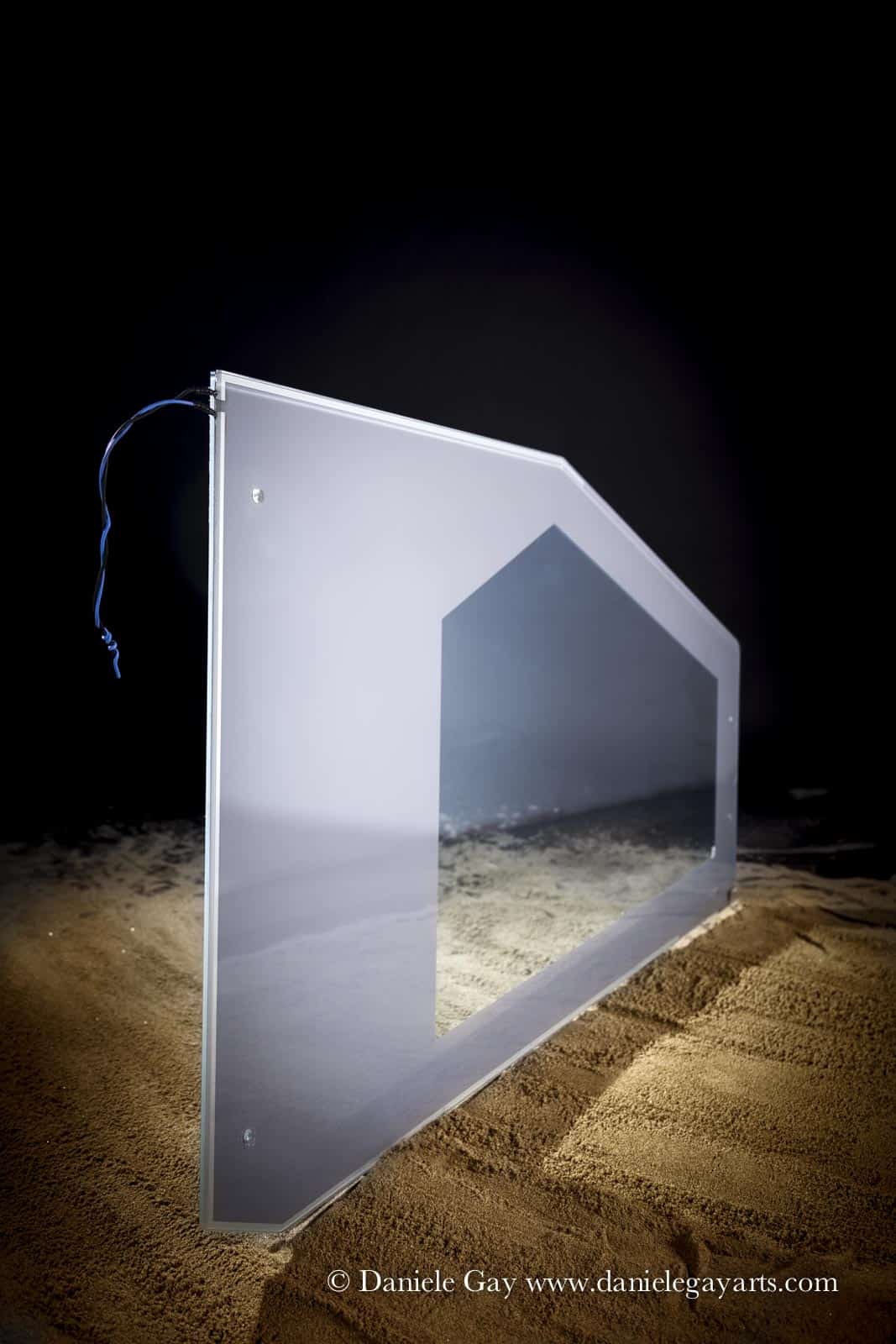

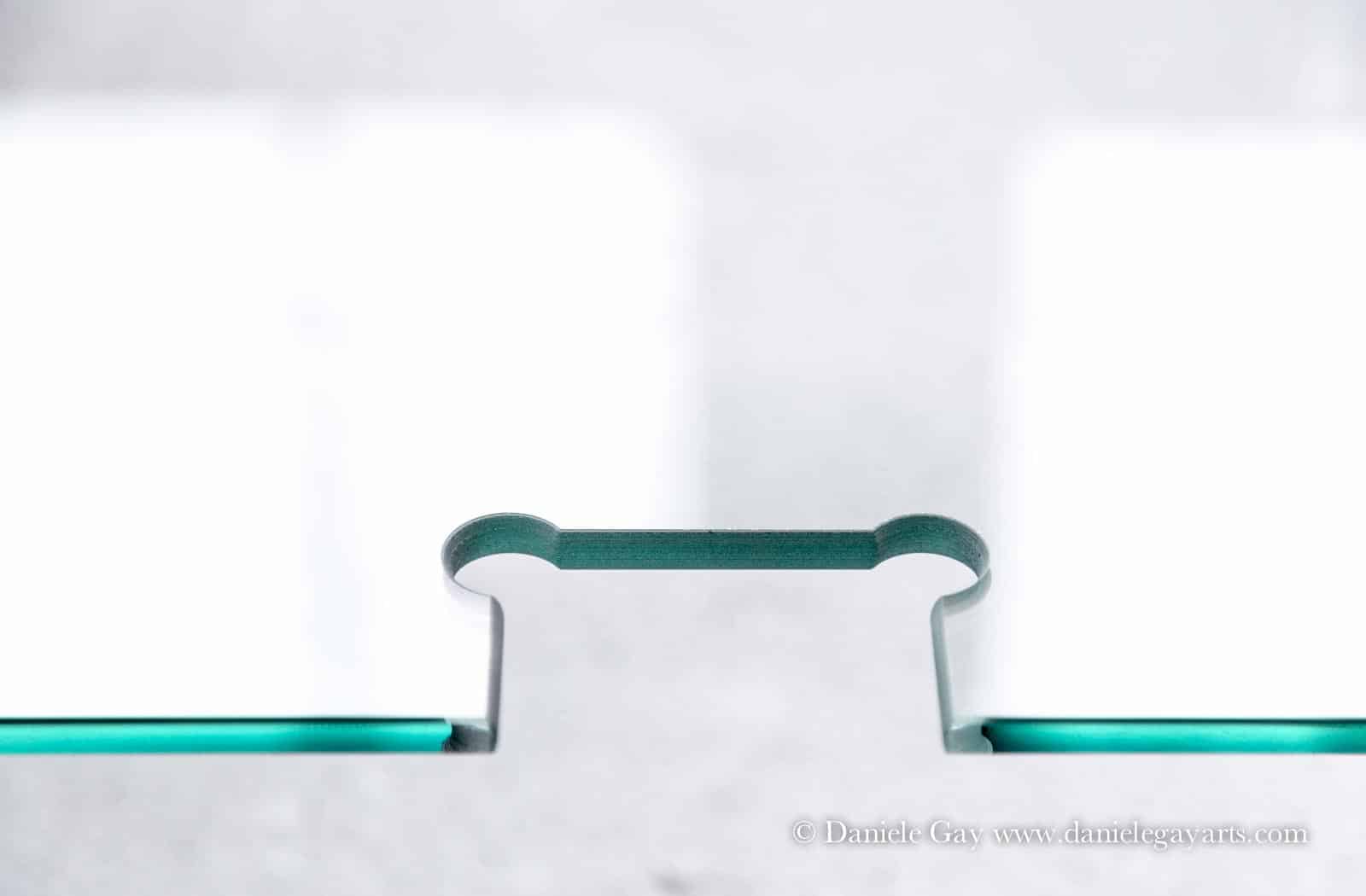

Incollaggio

La nostra azienda produce da sempre vetri incollati a ultravioletti. Questa tecnica permette di ottenere un prodotto pulito e senza tracce, con un’elevata resistenza meccanica. Realizziamo anche incollaggi di vetro con parti metalliche e/o profili in alluminio e materiali plastici in genere.

Le nostre teche sono customizzate, utilizzando vetri delle più svariate finiture e forme: chiaro, colorato, a basso contenuto di ferro, piano temprato ma anche curvato temprato.